>Top 3. Lithium-ion (LIB) Battery:

- The tremendous growth in high-power portable electronic devices (cellular phone, note PC, and video recorder) has increased the demand for lightweight.

- features: high density, no memory effect, low self-discharge, and safety risks when damaged.

- Li+ move from the negative electrode to the positive electrode during discharge.

- Li+ battery uses an intercalated Li compound as one electrode material, compared to the metallic Li used in a non-rechargeable Li battery.

- mostly based on LiCoO2

- LiFePO4;LiMn2O4, and $Li_2MnO_3 (LMO),andLiNiMnCoO_2 (LMC)$ are lower energy density but longer lives and less likelihood of fire or explosion.

- LiNiCoAlO2 (NCA) and Li4Ti5O12 (LTO) for particular niche roles.

- >Top Until recently, the most common rechargeable battery was Ni-Cd (nicad) battery.

- The electrode reactions are the following:

- Cathode: 2NiO(OH)+2H2O+2e−→2Ni(OH)2+2OH−

- Anode: Cd+2OH−→Cd(OH)2+2e−

- A single nicad voltaic cell has an emf of 1.30V; typically contain more cells in series to produce higher emfs.

- But Cd is a toxic heavy metal; rough 1.5B nicad batteries are produced annually.

- Development of NiMH battery:

- Anode consists of a metal alloy, such as ZrNi2, that has the ability to absorb H2 atoms.

- During oxidization at the anode, H2 atoms are released as H2O

- >Top The newest rechargeable battery to receive large use in consumer electronic (and EV), Li-ion batteries achieve a greater energy density.

- Li-ion battery achieves a greater energy density than Ni-based battery.

- Li-ion can be inserted into layers of graphite.

- During discharge Li-ions migrate between two different layered materials that serve as the anode and cathode of the cell.

- History of development of LIB:

- 1973: Adam Heller proposed lithium thionyl chloride battery.

- 1977: Samar Basu demonstrted electrochemical intercalation of Li in graphite.

- 1979: Ned A. Godshall, and in 1980 John Goodenough and Koichi Mizushima both demonstrated a rechargeable lithium cell in 4V using LiCoO2 as the positive electrode and Li metal as the negative electrode.

- 1980: Richard Yazami demonstrated the reversible electrochemical intercalation of Li in graphite.

- 1982: Godshall et al. were awarded US Patent on the use of LiCoO2

- 1983: Michael Thackeray, John Goodenough et al. further developed manganese spinel as a positive electrode.

- 1985: Akira Yoshino assembled prototype cell using carbonaceous material into which Li+ could be inserted as one electrode, and LiCoO2 as the other. By using materials without metallic Li, safety was dramatically improved. LiCoO2 enabled industrial-scale production.

- Commercial production:

- 1991: Sony and Asahi Kasei released first commercial LIB.

- 2011: LIB accounted 66% of all portable secondary battery sales in Japan.

- 2012: John Goodenough, Rachid Yazami and Akira Yoshino received 2013 IEEE medal for environmental and safety technologies of LIB.

- 2014: Then National Academy of Engineering recognized John Goodenough, Yoshio Nishi, Rachid Yamami and Akira Yoshino for their pioneering efforts in the field.

- 2016: Global LIB production capacity was 28GWh, with 16.4 GWh in China.

- >Top Tesla's Gigafactory ($5B):

- Panasonic reached agreement with Tesla to invest $1.6B in a factory, leading battery cell production of manufacturing.

- Production Group of LIB:

- Tesla/Panasonic Group

- Nissan/AESC (Nissan+NEC) Group

- GM/VW/LG Chem Group

- Mitsubishi/GS Yuasa/Toshiba Group

- Gigafactory-1: Reno, Nevada, US;

- Tesla held a grand opening on 2016/7/29, having only 3/21 blocs completion of the Gigafactory; which began mass production in 2017/1; expected to be completed by 2020.

- the factory is aligned on true north, is designed to be energy self-reliant (solar, wind, and geothermal), largest footprint in the world.

- Model-3 production ramped up to about 5,000

- Gigafactory-2: Buffalo, New York

- Gigafactory-3: Shanghai, China; began construction

- Gigafactory-4?: in Europe, plans underway

- EV Battery production <Fig.>:

- CATL (Comtemporary Amperex Technology, 宁德时代新能源科技): having plan to produce 88GWh by around 2020.

- BYD Company Ltd. (比亚迪股份): will produce 60GWh in 青海省 by 2020; particulary higher energy density battery of NMC811 (Ni8-Mn1-Co1 cathode) than MNC622 (Ni6-Mn2-Co2)

- it is importnat to decrease use of rare metal Co from 2 to 1.

- Co is said as 'the Wall of EV Proliferation', which is mostly mined unstable DRC (Democratic Republic of Congo)

- Tesla aims to reduce Co in producing NCA (Ni-Co-Al) battery using only 3% of Co.

|

3. リチウムイオン電池:

- energy density: エネルギー密度 Wh/kg, or Wh/m3

- ramp up: increase the level

- electrolyte: 電解質

- thionyl: チオニル基

- NEV: 新能源车

|

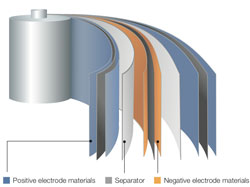

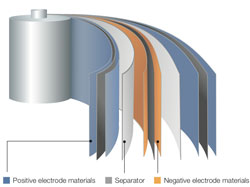

- Li-ion Battery (LIB) structure:

- Positive electrode: LiCoO2;LiMn2O4;LiFePO4

- Negative electrode: C;Si;SnO2

- Electrolyte: LiPF6;LiClO4

- AA Size (L) and 18650 for Tesla Model-S; Tesla says that now new 21700 type battery with 70mm-L, 21mm-D & 24.245mm3, which is bigger (46%), improved energy efficiency about 15%, energy density 877.5Wh/L and cell capacity 21.275Wh than 18650 type battery.

- Tesla's Gigafactory-1:

- EV Battery Production Share:

|

>Top <Next Generation Cathode - NMC 811>

- Various Li-ion Batteries:

-

| LiCoO2 |

LCO |

MobilePhone, Laptop PC, Camera |

| LiMn2O4 |

LMO |

Elec tool, Medical, Hobby |

| LiFePO4 |

LFP |

Elec tool, Medical, Hobby |

| LiNiMnCoO2 |

NMC |

Elec tool, Medical, Hobby |

| LiNiCoAlO2 |

NCA |

EV, Gridstorage |

| Li4Ti5O12 |

LTO |

EV, Gridstorage |

- NMC (Ni-Mn-Co) Cathode:

- This is the next-generation cathode - better and chearper, pushing EVs beyond 500km driving range and soon to price parity with ICE (Internal Combustion Engine).

- LIB compostion <Fig.>:

NMC811 is a cathode compostion with 80% Ni 10% Mn, and 10% Co. NMC cthodes with different Ni-Mn-Co compositions have been around for almost 20 years. Following the initial commercil success of NMC111 (as NMC333, NMC cathodes have become mainstream, being used in BMW-i3, Chevy Bolt, or new Nissan Leaf.

- Industry has been improving NMC technology by steadily increasinng Ni content (e.g. NMC433, NMC532, or most recent NMC622)

- The cells have higher capacity and lower weight; the battery packs store more energy and better driving range.

- It is NCA (Ni80-Co15-Al), but are doped with Al as opposed to Mn.

- >Top Ni is largely responsible for cathode capacity, with Mn and Co helping chemical and structure stability.

- 20% increase of Ni content (from NMC622 to NMC 811) pushes the capacity of NMC811 to around 200 mAh/g (discharge potential 3.8V) <Fig.>.

- Co Price (LME):

Co is very expensive with very questionable supply chain (like Kawama mine, Congo). Note, cathode materials account for about 1/4 of the cell cost. While Ni and Mn prices are relatively low and steady, the cost of Co skyrockted by more than 200% (from 35Kto75K/ton in 2017 alone)

-

- NMC811 is more sensitive chemistry; requiring improved synthetic processes than NMC333 or even NMC622.

- NMC is synthesized with Ni in oxidised state Ni3+, largely due to instabliity of Ni3+ ion at high synthetic temperatures.

- NMC comes alog with undersirable residues mainly Li-based that need to be removed or pssivated.

- NMC is also sensitive to moisture and air.

- Fully oxidised Ni4+ is reactive and so its exessive amount increase unwanted side reaction with the electrolyte.

- Capcity and cycle life don't necessarily go together for NMC811.

- Ni-rich NMC cathodes are sensitive to elevated temperature - release more O2 than their counter parts; also undergo more structural changes. <Fig.>

- LG CHem and SK Innovation claim NMC811 will be in mass production by the end of 2019, but safety of NMC811suggest the timescals might be more conservative.

- NCA development:

- Note, NCA technology (by Panasonic and Tesla) is developing as well. It's very similar to NMC811, whether you consider its Ni-rich chemistry, superior capacity, more complicated manufacturing, or stability issues.

- Tesla supplied ESS (Energy Storage System) in South Australia.

- World's largest ESS with capacity 100/129MWh, which was constructed within 100 days.

- This ESS Farm having 315MW capacity is used as the backup of Neoen's Hornsdale Wind Farm near Jamestown to stabilize the grid in the summer..

- Tesla decided to use Samsung SDI cells to make it on time.

- The cost is estimated at some $50M.

|

- LIB Compostion: (Li/Ni/Co/Mn/Al)

- LIB Capacity:

- LIB Temperature Sensitivity:

- LIB Structurel Changes:

| Gr7 |

Gr8 |

Gr9 |

Gr10 |

Gr11 |

Gr12 |

Gr13 |

| |

|

|

|

|

|

Al |

| Mn |

Fe |

Co |

Ni |

Cu |

Zn |

Ga |

| Tc |

Ru |

Rh |

Pd |

Ag |

Cd |

In |

| Re |

Os |

Ir |

Pt |

Au |

Hg |

Tl |

|