Vision of "Fab-Soicety"

Category: ICT

Published: 2014

#1502b

Institute for Information and Communications Policy (IICP), MIC

15125u/18117r

Title

Report on Vision of "Fab-Society"

ファブ社会の展望

Index

Tag

3D Printer; ICTF; Physital; Laser cutter; Milling machine; FabLab Charter; Sigmoid; Standardization of 3D; Design-conscious; CGM/CGT; Creative Commons; Ecosystem of Digital Fabrication;

Why?

- This is the report issued from Institute for Information and Communication Policy, an organization under Ministry of Internal Affairs & Communications.

- As this theme is focussed during the discussion of the training program in Jan. 2015 at JICA-Okinawa, the essence of the report is translated herein for the foreign trainees.

- This report is published subject to 'Creative Commons' BY (attribution).

- Re: 1502_visonoffabsociety.pptx

- Re: 1502_DigitalFab_MIC_org.pdf

- 本レポートは、総務省情報通信政策研究所による「ファブ社会の展望に関する検討会」報告書である。

- 2015年1月の沖縄JICAでの研修での議論で本テーマが注目されたので、その要旨を海外からの研修生向けに抄訳する。

- 本レポートはCreative Commons, BYで出版されている。

Summary

Keywords

>Top 0. Preface:

- Recent development of '3D Printer' gives a big impact on the method of manufacturing; regarded as the third media device in addition to video camera and inkjet printer.

- Particularly, it gives great empowerment to individuals to create or fabricate something; which is called "personal fabrication" as a kind of new culture.

- Similar process has occurred, just like as the computer became PC developed from mainframe, or DTP became possible with personal inkjet printer; smart manufacturing or personal fabrication became available with using 3D printer.

- This trend may cause a big change of logistics; enabling to send data to a nearer place where materials exist, or make production nearer to the consumer.

- As the Internet caused a paradigm shift towards autonomous, distributed and collaborative environment, this trend may cause similar shift in production system.

- It could be said that such digital fabrication be the last one piece to complete information society; where 'ICT' should be called as 'ICFT (Information, Communication, & Fabrication Technology).

- Additional issue should be considered such as PL in digital fabrication, just like the copyright issue in digital content.

- Thus we would propose a new jargon of 'Physital' merging with Physical and Digital; as we would live in a hybrid domain of information and material.

- The above message by Hiroya Tanaka, chairman of the study group of vision of Fab-Society. (Jun., 2014)

0.

- 3D Printer

- the third media

- personal fabrication

- computer ←mainframe; DTP←inkjet printer; personal fabrication ←3D printer

- logistics may be affected

- autonomous, distribute and collaborative environment

- ICFT (Information, Communication, & Fabrication Technology)

- PL in digital fabrication

- Physital = Physical + Digital

>Top 1. Advent of Physital Society and change of manufacturing:

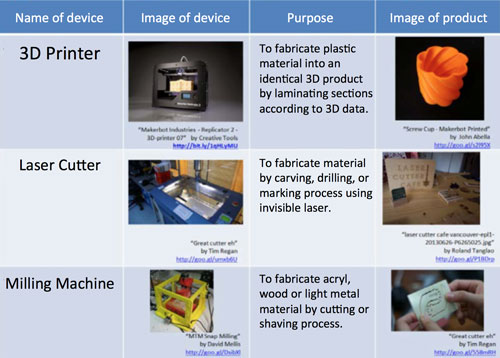

- Digital Fabricator is a machine tool or device to fabricate digital data into product made from paper, wood, cloth, plastics, metal, etc. <→Fig.>

- These devices are formally installed in a factory and used by a certain specialists. But nowadays it has rapidly developed that more smaller, high-qualified, and less expensive devices which became available by anyone.

- Digital fabricator changed the concept of things; which enable to make the thing from 3D data, conversely to store the thing in 3D data. This means the thing can exist concurrently both in real space and cyber (digital) space. This can also change manufacturing, logistics and consumption; or the change the society itself.

- Smaller device connected to Internet:

- Digital fabricators are 1) 3D printer, 2) laser cutter, 3) milling machine, etc., all of which had been expensive, but the price is reducing due to technical advancement, being smaller in size and having more performance in addition to the patent expiry.

- 3D Printer was originally invented for industrial purpose fabricating prototype around 1980.

- Cheaper and smaller sized 3D printers have been made one after another; because the patent of thermal dissolving & laminating method held by major 3D printing companies had been expired since 2006.

- History repeats itself in downsizing of computers; smart phones we are daily using have the similar capacity of super computer 30 years ago. Mainframe occupying 167 sq. meter of space has evolved to minicomputer, PC, and then smart phone. <→Fig.>

- Smaller sized digital fabricators are installed in various workshops as common facilities, which are open to citizens, giving more opportunities to use them.

- Such digital fabricators are connected to Internet.

- Networked set of digital fabricators would be instantly a smart production line, which could be installed anywhere; near to materials supplying place or consuming place. (Distributed production)

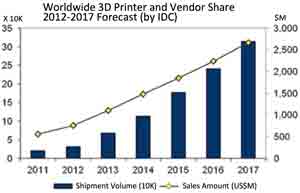

- 3D Printer Forecast worldwide 2012 -2017: <→Fig.>

- CAGR 59% in volume, 29% in sales (by IDC);

- Volume in 2017: 315,000

- Sales in 2017: $2.7B

- Birth of Physital (Physical + Digital) Space: <→Fig.>

- Real production needs a center of production, making metal mold (dice) and small variety & large quantity production.

- Physital production enables large variety & small quantity production.

- ICTF Society = Information, Communication, & Fabrication

- Process innovation by Digital Fabricator:

- Process Innovation:

- Shortening R&D, design and prototyping time.

- No need of making mold (dice)

- Generalization of customized production

- Reduction of production cost and period: initial cost 1/50 and production period 1/10 is possible.

- available to use strong materials, and to make complicated forms with .

- Large variety & small quantity production:

- artificial hand/leg/tooth/internal organ

- preservation of historical heritage

- replica as touchable display

- attachment of musical instrument

- <future>

- cooking from cooking ingredients

- on the moon production using moon soil powder

- Personal Fabrication:

- Even an individual, designer, creator, or SW engineer can participate production. (DIY)

- Cost reduction is available by not only 3D printer, but also 3D scanner, 3D modeling tool, which are made by OSS.

- The boundary of producer and consumer. or professional and amateur is getting ambiguous.

- Makers Space or FabLab worldwide:

- There are many Makers Spaces or FabLabs in the world which support various activities of personal fabrication.

- In 2006, the first TechShop was opened in Menlo Park in Silicon Valley as a common workshop of DIY digital fabrication.

- Jack Dorsey, one of founders of Twitter made a prototype of 'Square'; once becomes a member of TechShop, anyone can use facilities of woodcraft, lathe, weld.

- Neil Gershenfeld of MIT made 'FabLab', where anyone can practice personal fabrication using 3D Printer, Laser cutter, 3D scanner, etc.; which grows in 120 places in 30 countries.

- 'FabLabs' are operating according to the common FabLab Charter <→Charter>, which functions as regional hub center.

- In Japan, FabLab Japan started its activities in the spring of 2010, having seven FabLabs operating in such cities as in Kamakura, Tsukuba, Shibuya, Osaka, Sendai, Yokohama, and Ohita.

- The 9th World FabLab Conference was held in Yokohama in 21-27, Aug., 2013, where 192 FabLab activists from 40 countries participated.

- Process Innovation - Social Fabrication:

- It is remarkable that information & technology of digital manufacturing can be shared via Internet as 'Social Fabrication' contributing Open Design or Open Innovation.

- The output made in FabLab is principally open; anyone can utilize or refine the idea or design according to local context; i.e.; glocal manufacturing combining local production using global network.

- E.g.: Japanese leather-crafter made slippers by Laser cutter and open the data, then an operation of FabLab in Kenya arranged the shape, material, and design adaptive to the local needs, and delivered to the grandmother of President Obama, pressing the face of her grandson. This is an example of the data was transferred to other country and remade in different context.

- Thingverse services: 3D Printer information are uploaded in creative commons; 130,000 members can download and use the data from the site.

- It is anticipated that such as Home Centers service with digital fabricators, or a consumer can ask a corporate factory to make the product according to the data on digital fabricator.

1. :

- Digital Fabricator:

The Fablab Charter

- What is a fab lab?

Fab labs are global network of local labs, enabling invention by providing access to tools for digital fabrication

- What's in a fab lab?

Fab labs share an evolving inventory of core capabilities to make (almost) anything, allowing people and projects to be shared.

- What does the fab lab network provide?

Operational, educational, technical, financial, and logistical assistance beyond what's available within one lab

- Who can use a fab lab?

Fab labs are available as a community resource, offering open access for individuals as well as scheduled access for programs.

- What are your responsibilities?

safty: not hurting people or machines

operations: assisting with cleaning, maintaining, and improving the lab

knowledge: contributing to documentation and instruction.

- Who owns fab lab inventions?

Designs and processes developed in fab labs can be protected and sold however an inventor chooses, but should remain available for individuals to use and learn from

- How can businesses use a fab lab?

Commercial activities can be prototyped and incubated in a fab lab, but they must not conflict with other uses, they should grow beyond rather than within the lab, and they are expected to benefit the inventors, labs, and networks that contribute to their success

- draft made on: October 20, 2012

>Top 2. Prediction of advent of Fab-Society:

- Fab-Society as a social innovation (by Shumpei Kumon):

- Present age is positioned as the last stage of modernization; the next age will be Fab-Society. <→Fig.>

- Fab-Society is just located at the crossing of the last stage (3rd) of the Industrial Revolution and the first stage of the Information Revolution.

- Social Revolution shifts according to S-shaped curve (Sigmoid) ; in Advent, Breakthrough, Maturity, and Fixity stages. <→Fig.>

- Various social phenomena appear gradually being formed, surely in existence that nobody can denies. The next begins as Breakthrough stage; whose e will produce bubble, then its adjustment occurs and shifts to the next Maturity stage. Then, it will be established and will have stable relationship in a society as Fixity stage.

- Flow of Industrialization:

-

Period

Phase

Starts

Feature

Main industry

1st Industrial Revolution

Advent

1800 -

buy consumer goods and consume them

Textile

2nd Industrial Revolution

Break-through

1900 -

buy machines and make services

Car, Electronics

3rd Industrial Revolution

Maturity

2000 -

make things by themselves using Web

Digital Fab.

- Three Phases of Digitalization & Socialization:

-

3rd Industrial Revo.

(Digitalization)

Advent: Info. process from later 20C

(Net/Web society)

Computing

-Internet

-Cloud)

Communication

-Social media

-Social NW

Breakthrough: Things process from earlier 21C

(Fab-society)

Manufacturing

-Digital machines

-Material supply, recycle infra.

Fabrication

-FabLab NW

-BioLab NW

Maturity: System/frame process

(Peer society)

Servicing

-Care robot, etc.

Solution

-SocLab NW

- Fab-Society as the premise society of Internet (by Jun Murai):

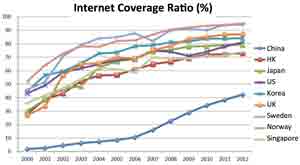

- Internet coverage ratio: about 35% worldwide, and more than 70% in advanced countries; by 2020 average worldwide more than 70%. <→Fig.>

- We need to consider the Internet as the premise of everything.

- Since latter half of 1990s, commercial use of Internet started.

- Internet grew rapidly after Y2K (Year 2000) problem in 2000.

- 9.11.2001 caused to begin to control the Internet by filtering or blocking. But the Internet has become global digital space; which raised the issue of 'Interne Neutrality'.

- In 2011, UN reported, "The Internet access is the human right."

- Internet started from connecting computers, then connecting humans, then it became sensors connecting devices or everything. The data on the Internet are distributed and shared.

- Internet is not only the global network, but it become local connecting with data and GPS, by which humans being traceable forming free community whether is closed or open. Wireless environment surely promote human free mobility.

- The society means each participant can decide what to do by himself.

- Issues of Digital Fabrication: >Top

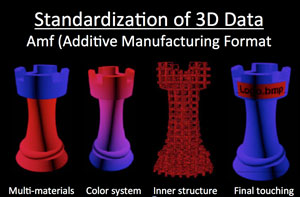

Standardization of 3D Printer is now in process; Amf (Additive Manufacturing Format) is consider in ASTM (American Society of Testing and Materials), which includes 1) multi-materials, 2) color system, 3) instruction of internal structure, 4) finishing touches, etc. <→Fig.>

- Acceleration of User Innovation in Fab-Society, (by Susumu Ogawa):

- Customer' needs are diversifying, particularly in advanced countries; customers could not find what really they want.

- In Fab-Society, the trend of user innovation becomes conspicuous.

- Ratio of adding additional functions more than 10% of existing products:<→Chart>

- Customer Investment: <→Chart>

- Even in Japan, considering the above 13%; user innovation cannot be neglected.

- User innovation from the viewpoint of corporation:

- User innovation does not necessarily valued by corporations; only 4% of customers can make innovations, which does not affect market research of the corporations.

- But here is a value of user innovation; corporations have definite assessment of their products, hardly accept different usages other than the maker's assumption

- E.g.: to use masking tapes as a decoration of notebooks or envelopes.

- User innovation has been usually closed, enclosed in personal usage; but since Makers' revolution as well as creative commons are going to change these situations.

- Corporations who have acknowledged the possibility of user innovations started to co-create with users.

- E.g.: Quirky, elephant-design, Lego

- In Fab-Society, products made by individuals could contribute the next stage; scale-out, proper quantity, response to globalization, or creation of more innovative society.

- >Top Design-conscious Fab-Society (by Fumio Nanjo):

- Rise of active investment in design, or creative industries, particularly in Asian countries; this trend shows the shift to software-centric economics from heavy, thick, long & big industries.

- Function of public facilities such as Art Museum, Design center, FabLab, Innovation Center should be the places for relaxation and refreshment for many citizens, where many creators gather, being a platform of creative industries.

- The present is the age of acentric world, or multi-plural culture; unique in Asian sense of values;

- Formerly, NY, London, & Paris are the world center; but now there are more centers like Mumbai, Shanghai, or Tokyo; such multipolar cities are connected by information and traffic networks.

- Asian design has been recognized anew;

- To make Japan more creative society: 'Cool Japan' by hybrid of tradition and technology, or Japanese aesthetic values.

- Marketing or branding strategy; to foster more producers.

- Diversity, or being different would be another keyword;

- Japanese tend to assess more result and content rather than its process.

- Reverse chain is expected; from individual rather than from major corporations, emphasizing individual inspiration, collaboration and shared economy by people.

2.

・Additional functions by customers:

Ratio of Customer Innovators

(>18 years old)

Japan (n= 2000)

US

(n= 1992)

UK (n= 1173)

Manufacturing

1.7%

2.9%

2.1%

Improvement

2.5%

2.8%

4.5%

Both

0.5%

0.5%

0.5%

Total %

3.7%

5.2%

6.1%

Total # (est.)

4.7M

16M

2.9M

・Customer Investment:

Amount of Investment by Customers:

Japan

US

UK

Customer innovator

- days spent per year

5.5d

9.9d

7.1d

- invested amount (US$)

$1479

$1725

$1801

Annual expenses of consumer innovators

$5.8B

$20.2B

$5.2B

R&D expenses of consumer makers

$43.4B

$62.0B

$3.6B

Ratio of expenses (Innovator/ Makers)

13%

36%

144%

>Top 3. Changes in Social Structure by Fab-Society:

- Key concept of Fab-Society:

- Fusion of cyber space and real space; human activities between digital and physical space (advent of Physital space).

- More free and affluent ways of manufacturing style; large variety and small quantity production

- Fab Society is a society which enables anyone to make any quantity of products at anywhere and anytime.

- Change in production, logistics, and consumption:

- In Fab-Society, existing manufacturers and corporations continue to exist; but there appear such individuals who own production media, entering diversified production.

- Rise of products with wider blank spaces;

- Consumers can repair the products by themselves.

- Method of manufacturing will be a commodity; which makes decrease the value of rare products.

- Cost structure will drastically change: <→Fig.>

- Changes in Japanese style of manufacturing:

- In arts or music, there are many CGM (Consumer Generated Media), but very few in manufacturing field.

- Coexistence of major manufacturing factories of corporations, which will also adopt 3D Printer, etc.

- But, individuals and communities will promote CGT (Consumer Generated Things). Major factories will cooperate in commercial manufacturing of these prototypes proposed by them. (Open Factory)

- Logistics and sales of materials and data will be activated.

- The payment will be bartering or C2C transaction increases.

- Cloud funding will increase in activity.

- Home delivery of goods which can be made by 3D Printer will be needless; or transaction of 3D data will increase.

- 'Assessment Economy' will appear.

- Labor style will change is such as:

- Individual or community manufactures will increase.

- Alliance with corporations will increase.

- Employment of outcomes/results-based payment; more liquidity in employment

- Changes in life-style:

- Social media

will prevail; more active community on the network.

- Open Source Software will prevail, promoting secondary creation using digital contents.

- Change in Education:

- Originality or uniqueness will be emphasized.

- Self-studying getting online support by peers.

- Teachers and lecturers will need ability of designing learning tools; with changing curriculum of science combining fine arts, technology, and home economics; ability of ICFT.

- More emphasizing on social participation or contribution, and practical education, work session; or more horizontal education in communities.

- Change in legislative system:

- New framework of copyright is urged.

- Creative Commons will be applied to manufacturing and secondary creation.

- Treatment of Product Liability; RFID will be embedded during 3D printing for traceability of the product.

- Change in Living Sphere:

- More glocal development; local production for local consumption, using local materials (more ecological viewpoint).

3.

- Cost Structure of value chain in Fab-Society:

>Top 4. Issues for healthy development of Fab-Society:

- Intellectual Property: new framework is needed:

- Social IP, or Open Registered Rights Licenses will be needed; in particular, Creative Commons, GPL Licenses.

- More traceability, visualization will be needed

- Rapid registration of IP, reducing IP troubles.

- Global repository for global IP management system.

- Copyright issue for 3D printing.

- Product Liability (PL):

- Private use is not applicable even in the present PL law. What will be of PL in Fab-Society.

- Some level of PL are needed, subject to information disclosure and regular review by community or the third party.

- What would be quality control (E.g. JIS Mark), or insurance system, including privacy issue? Or, what would be 'repair rights'?

- What would be production and ownership of hazardous material

- Standardization of Format:

- Standardization of format of various facilities are needed to use as an integrated system.

- Ecosystem of Digital Fabrication is considered in four layers: <→Fig.>

- Open design architecture, which assumes digital fabrication is made by plural participants.

- Keeping logs of making process, vicarious experience, compensation per contribution; clarification of PL, etc.

- Architecture of networked digital fab machines, including remote control.

- Production & logistics of IoT.

- Traceability by embedded RFID; all digital products can be traceable.

- HRD in Fab-Society, particularly development of hybrid-capable or fused expertise; design + engineering, design + facilitation, engineering + facilitation; and tolerance to failure.

- It is more important what to make than how to make; discoverability

- Archive and publication:

- Japan has shown unique strength in design and modeling.

- Publication of digital contents, preservation of digital archive; introduction of various case studies of social fabrication.

- Prominent areas are medical, health care, rehabilitation and supporting devices, robotics, etc.

4.

- Ecosystem of Digital Fabrication:

Comment

- There are several ways of making things: 1) to carve from a bigger material, 2) to mold smaller materials, 3) to assemble many parts of materials, 4) to transform from different phase (from liquid to solid), 5) to grow by crystallization, etc.

- Creatures are making things quite differently, which can make materials themselves from the protein, or amino acids.

- Digital fabrication seems to be an integrated way of making things; which combines the above various ways of making methods by carving, molding, assembling, or transforming except for making the materials themselves. And it remarkable that the instruction of making comes from remote center via network.

- 物作りにはいくつかの方法がある。1) より大きなものからの彫刻、2) より小さな材料の鋳造, 3) 多くの部品の組み立て、4) 相転換による成形 (液体から固体)、5) 結晶による成長など。

- 生物は、全く異なる物作りをしている。材料そのものを蛋白質やアミノ酸から作り出している。

- デジタルファブは、これら彫刻、鋳造、組み合わせ、相転換の手法を総合した物作りのように見える。但し、材料そのものは作らないが。しかもその物作りの司令塔はネットを通じて遠方からやってくることが画期的である。

Vision of "Fab-Soicety"

|

Category: ICT |

|

Institute for Information and Communications Policy (IICP), MIC |

15125u/18117r |

Title |

Report on Vision of "Fab-Society" |

ファブ社会の展望 |

|---|---|---|

Index |

||

Tag |

3D Printer; ICTF; Physital; Laser cutter; Milling machine; FabLab Charter; Sigmoid; Standardization of 3D; Design-conscious; CGM/CGT; Creative Commons; Ecosystem of Digital Fabrication; |

|

Why? |

|

|

Summary |

Keywords |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

>Top 0. Preface:

|

0.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

>Top 1. Advent of Physital Society and change of manufacturing:

|

1. :

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

>Top 2. Prediction of advent of Fab-Society:

|

2. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ratio of Customer Innovators (>18 years old) |

|||

| Japan (n= 2000) | US (n= 1992) |

UK (n= 1173) | |

| Manufacturing | 1.7% | 2.9% | 2.1% |

| Improvement | 2.5% | 2.8% | 4.5% |

| Both | 0.5% | 0.5% | 0.5% |

| Total % | 3.7% | 5.2% | 6.1% |

| Total # (est.) | 4.7M | 16M | 2.9M |

・Customer Investment:

| Amount of Investment by Customers: | |||

| Japan | US | UK | |

| Customer innovator | |||

| - days spent per year | 5.5d | 9.9d | 7.1d |

| - invested amount (US$) | $1479 | $1725 | $1801 |

| Annual expenses of consumer innovators | $5.8B | $20.2B | $5.2B |

| R&D expenses of consumer makers | $43.4B | $62.0B | $3.6B |

| Ratio of expenses (Innovator/ Makers) | 13% | 36% | 144% |

>Top 3. Changes in Social Structure by Fab-Society:

- Key concept of Fab-Society:

- Fusion of cyber space and real space; human activities between digital and physical space (advent of Physital space).

- More free and affluent ways of manufacturing style; large variety and small quantity production

- Fab Society is a society which enables anyone to make any quantity of products at anywhere and anytime.

- Change in production, logistics, and consumption:

- In Fab-Society, existing manufacturers and corporations continue to exist; but there appear such individuals who own production media, entering diversified production.

- Rise of products with wider blank spaces;

- Consumers can repair the products by themselves.

- Method of manufacturing will be a commodity; which makes decrease the value of rare products.

- Cost structure will drastically change: <→Fig.>

- Changes in Japanese style of manufacturing:

- In arts or music, there are many CGM (Consumer Generated Media), but very few in manufacturing field.

- Coexistence of major manufacturing factories of corporations, which will also adopt 3D Printer, etc.

- But, individuals and communities will promote CGT (Consumer Generated Things). Major factories will cooperate in commercial manufacturing of these prototypes proposed by them. (Open Factory)

- Logistics and sales of materials and data will be activated.

- The payment will be bartering or C2C transaction increases.

- Cloud funding will increase in activity.

- Home delivery of goods which can be made by 3D Printer will be needless; or transaction of 3D data will increase.

- 'Assessment Economy' will appear.

- Labor style will change is such as:

- Individual or community manufactures will increase.

- Alliance with corporations will increase.

- Employment of outcomes/results-based payment; more liquidity in employment

- Changes in life-style:

- Social media will prevail; more active community on the network.

- Open Source Software will prevail, promoting secondary creation using digital contents.

- Change in Education:

- Originality or uniqueness will be emphasized.

- Self-studying getting online support by peers.

- Teachers and lecturers will need ability of designing learning tools; with changing curriculum of science combining fine arts, technology, and home economics; ability of ICFT.

- More emphasizing on social participation or contribution, and practical education, work session; or more horizontal education in communities.

- Change in legislative system:

- New framework of copyright is urged.

- Creative Commons will be applied to manufacturing and secondary creation.

- Treatment of Product Liability; RFID will be embedded during 3D printing for traceability of the product.

- Change in Living Sphere:

- More glocal development; local production for local consumption, using local materials (more ecological viewpoint).

3.

- Cost Structure of value chain in Fab-Society:

>Top 4. Issues for healthy development of Fab-Society:

- Intellectual Property: new framework is needed:

- Social IP, or Open Registered Rights Licenses will be needed; in particular, Creative Commons, GPL Licenses.

- More traceability, visualization will be needed

- Rapid registration of IP, reducing IP troubles.

- Global repository for global IP management system.

- Copyright issue for 3D printing.

- Product Liability (PL):

- Private use is not applicable even in the present PL law. What will be of PL in Fab-Society.

- Some level of PL are needed, subject to information disclosure and regular review by community or the third party.

- What would be quality control (E.g. JIS Mark), or insurance system, including privacy issue? Or, what would be 'repair rights'?

- What would be production and ownership of hazardous material

- Standardization of Format:

- Standardization of format of various facilities are needed to use as an integrated system.

- Ecosystem of Digital Fabrication is considered in four layers: <→Fig.>

- Open design architecture, which assumes digital fabrication is made by plural participants.

- Keeping logs of making process, vicarious experience, compensation per contribution; clarification of PL, etc.

- Architecture of networked digital fab machines, including remote control.

- Production & logistics of IoT.

- Traceability by embedded RFID; all digital products can be traceable.

- HRD in Fab-Society, particularly development of hybrid-capable or fused expertise; design + engineering, design + facilitation, engineering + facilitation; and tolerance to failure.

- It is more important what to make than how to make; discoverability

- Archive and publication:

- Japan has shown unique strength in design and modeling.

- Publication of digital contents, preservation of digital archive; introduction of various case studies of social fabrication.

- Prominent areas are medical, health care, rehabilitation and supporting devices, robotics, etc.

4.

- Ecosystem of Digital Fabrication:

Comment |

|

|