|

Capability Building CompetitionWhy Japanese Automobile Industry is strong?

|

Cat: ECO |

|---|---|---|

Takahiro Fujimoto (藤本隆宏) |

09612u/18212r |

Title

Capability Building Competition

能力構築競争

Index

- Industry observed from fiedl site:

- Essence in competiion in car industry:

- What is comepetency building competition:

- Why Japanese car industry has been strong?:

- Anatomy of manufacturing organization capability:

- Japanese car industry in 20C:

- Logic of emerging capability building:

- Trade friction as a supporting cast:

- Cooperative network supplementing competition:

- Catch-up from US and Europe:

- Copmetency building competition still continues:

Why?

-

Japan does not show competitiveenss in all manufacturing capability. Automobile industry is an unique or even exceptinal case, which has illustrated the image of manufacturing capability of Japan since 1980s.

-

This book focussed to analyse strengh and features of Japanese automobile industries comparing with those of foreign manufacturers.

-

During reading this book, it is reported that gigantic GM and Chrysler announced to apply Chapter 11. It seemed another 9.11: collapse of symbolic architecture of American capitalism.

- 日本はすべてのもの造りで競争力がある訳ではない。自動車産業はユニークであり、むしろ例外的であって、それが1980年代以降の日本の製造業のイメージを形作ってきた。

- 本書は日本の自動車産業の強さと特徴の分析について、海外メーカと比較しながら記述している。

- 本書を読んでいる途中で、巨大なGMの倒産発表のニュースが流れた。これはもう一つの9.11のようである。アメリカ資本主義の象徴的なアーキテクチャが崩壊したのである。

Resume

要約

>Top 0. Industry observed from field site:

- Since latter half of 1990s, Japanese car industry has continued to progress its productivity and to reduce development period, which could not result neither better evaluation in the market, nor corresponding financial outcome.

- It is believed that these are mostly caused by yen appreciation, continued recession, failure of corporate strategy, mistake of logistic strategy, financial loss, lack of branding, etc. But it has maintained that manufacturing capability at the filed site.

- When IT bubble was burst in US since 2000, Toyota style production system has been reevaluated.

- Competition brings another competition

- Price competition is not always the answer to the reality of industrial competition; dynamics of background competition will matter.

0. もの造りの現場からの産業論:

- 1990年代後半以降、日本の自動車産業は、生産性向上や開発期間の短縮かを継続的に達成したが、市場での表意かや財務業績につながらなかった。

- この要因は、円高、不況、企業戦略の失敗、流通戦略の失敗、財務面でのミス、ブランド力の欠如と言われたが、現場のもの造りは維持された。

- 2000年以降米国のITバブル崩壊後、トヨタスタイルの生産システムが再評価された。

- 競争が競争を呼ぶ。

- 価格競争だけでは産業競争の実態の説明にならない。背景にある競争のダイナミックスが重要

>Top 1. Essence of competition in car industry:

- In Japanese industries after WWII, it cannot be neglected that follow-the-leader competition will make competitive edge.

- Tenaciousness and endurance shown in Toyota production system, Just-in^time, TQC, etc. in Japanese car industry could be the origin of competitiveness.

- But most of Japanese other industries such as logistics, finance, various services, construction have shown lower productivity.

- Japanese economic power depends on export-oriented manufacturers, which shares half of manufacturers occupying 20% of GNP.

- During 1980s and 90s in particular, Japanese car industry has outstripped US and European ones in many indices such as assembly productivity, development productivity, development speed, inventory turnover rate, product quality, etc.

- In summary, manufacturers can be regarded as a system of organizational capability. Their pattern of long term development can attribute to their unique capability building competition.

1.

自動車産業における競争の本質:

- 戦後の日本の製造業では、横並びの競争が競争優位を生み出してきた面は無視できない。

- トヨタ生産方式、ジャストインタイム、TQCなどで示されたしぶとさと粘り強さが自動車産業の強さの源泉。

- 但し、日本の他の産業、流通、金融、サービス、建設などは低い生産性にとどまっている。

- 日本の経済力の強さは、GNPの20%を占める製造業の内の半分の輸出指向型の製造業に依存している。

- 特に、 1980年代90年代の日本の自動車産業は、組立生産性、開発生産性、開発スピード、在庫観点立、製造品質などで欧米メーカを凌駕していた、

- 要するに、製造業は組織能力のシステムと見なすことができる。それらの長期の開発パターンは各々のユニークな能力構築競争に起因する。

>Top 2. What is capability building competition?:

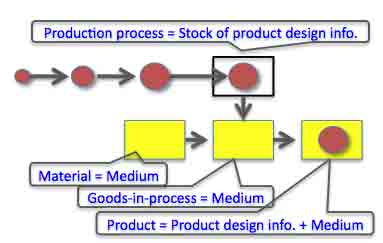

Production is transcription of design information:

Production is transcription of design information:

Any product bought from a corporation is a product which someone designed and installed it in a certain material.

- Product design is a kind of information in a broad sense, because it is a symbol or pattern described and saved as in a blueprint or a computer file.

- Production process = Stock of product design information

- Material = Medium

- Goods-in-process = Medium

- Product = Product design information + Medium

- What is competitiveness of a product?:

- Surface layer (visible) competitiveness: 4P

- Product

- Price

- Promotion (PR)

- Place of sales

- Deep layer (invisible) competitiveness: QCD&F

Productivity, production lead time, development lead time, and quality of conformance

- Quality: design quality, manufacturing quality

- Cost:

- Delivery: period from order to delivery of materials

- Flexibility:

degree of QCD which are less affected by external environment, mainly due to commoditized parts and generalized process.

- Capability Building Competition is a long-range battle.

- Market is rather permissive. Selection in a market has suspended term.

- Benchmarking: information about competitors' productivity, lead time, percent defective is limited.

- Process of capability building is emergent: This process cannot be controlled by caution in advance.

- A lucky hit, or unexpected things are what usually happens.

- Collaboration promotes competition:

- collaborate in acquiring organizational capacity and compete at cost of the final product.

2. 能力構築競争とは:

- 生産とは設計情報の転写である。<左図>

- 我々が企業から買う製品は、誰かが設計し、それを素材の中に仕込んだもの。

- 製品設計は、紙に書いて図面かしたりコンピュータ・ファイルとして制作した一種の記号やパターンであり、広義の情報である。

- 生産工程=製品設計情報のストック

- 素材=媒体

- 仕掛品=媒体

- 製品=製品設計情報+媒体

- 製品の競争力とは:

- 表層の競争力:4P

- Product

- Price

- Promotion

- Place of sales

- 深層の競争力:QCD&F

生産性、生産リードタイム、開発リードタイム、適合品質

- Quality

- Cost

- Delivery

- Flexibility:

外的環境要因の変動によって影響を受けない度合い

- 能力構築競争は長期戦:

- 市場はむしろ寛容。市場での淘汰には執行猶予期間がある。

- ベンチマーキング:ライバル企業の生産性、リードタイム、不良率などの情報は限られる

- 能力構築のプロセスは創発的:このプロセスは事前に慎重に管理することはできない。

- 怪我の功名、瓢箪から駒

- 協調が競争を促進する:

- 組織能力獲得では協調し、最終製品の価格では競争する。

- Idea of theory of evolution:

- The theory explains simultaneously stability & instability, and continuity & discontinuity of a system. Analogically,

- gene corresponds to organizational capability or organizational routine (customs and rules)

- emergency corresponds to mutation.

- complexity means not accidentally built

- rationality means survival in the end.

- Organizational capability contains three layers:

- Manufacturing capability: to make continuously products at lower cost, with higher quality and shorter period

- Improving capability: to improve continuously such QCD

- Evolutionary capability: to be able to evolve rapidly than the rivals

- Tenacious or tough learning capability:

- learn from own failure, from intended success, from unintended success, and from the other's success.

- Clients also evolve in their needs and product evaluation capability:

- Product integrity: sense of fitting life-style

- In car industry, there happened no revolution to change totally the concept of car.

- Core parts technology:

- Source of power: still unsettled since invention of gasoline internal-combustion engine in 1886 with other source of powers like steam engine or electro motor.

- But since 20C, advantage of gasoline engine became obvious.

- Competition between architecture:

- Original car design followed that of carriage; engine was installed under the seat, which was called horseless carriage

- Between middle and last 20C, both core parts technology and product architecture were almost unchanged.

- 進化論のアイデア:

- 進化論は、安定と不安定、連続と不連続を同時に説明する。例えると

- 遺伝子は、組織能力または組織ルーティン(慣行やルール)

- 創発は、突然変異

- 複雑性は、偶然に作られたものではないこと

- 合理性は、結局生き残ったこと

- 組織能力は3層から成る:

- もの造り能力

- 改善能力

- 進化能力

- しぶとい学習能力:

- 失敗から、意図した成功から、意図せざる成功から、他人の成功から学ぶ

- 顧客のニーズや商品評価能力もまた進化する。

- 製品統合性

- 自動車産業では、車のあり方を根本から変える革命は起こらなかった。

- コア部品技術:

- 動力源:1886年のガソリン内燃機関の発明以降も、蒸気機関や電気モータなど他の動力源の決着つかず

- 20Cになってから、ガソリンエンジンの優位性が確立した。

- アーキテクチャ間の競争:

- 当初の車は馬車のデザインを踏襲:エンジンは座席の下で、馬なし馬車

- 20C半ばから終わりにかけて、コア部品技術も製品アーキテクチャもほとんど変化なし。

>Top 3. Why Japanese car industry has been strong?:

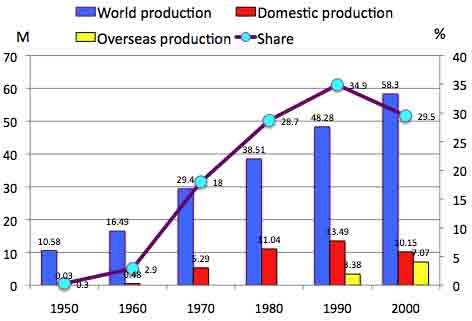

Car production (World and Japan) :

- Overseas production of Japanese car before 1980 is unclear, which was almost nil.

- Market share in 1990s was around 30% in North America, 10% in EU, 30% in non-car-producing Europe, and 50-90% in SE Asia.

- Japanese car industry became world major car producer in the last quarter of 20C.

- IMVP (The International Motor Vehicle Program) of MIT founded in 1979:

- conducted interdisciplinary research of comparison of deep layer competitiveness of each car industry, including benchmarking of productivity, product quality, and lead time.

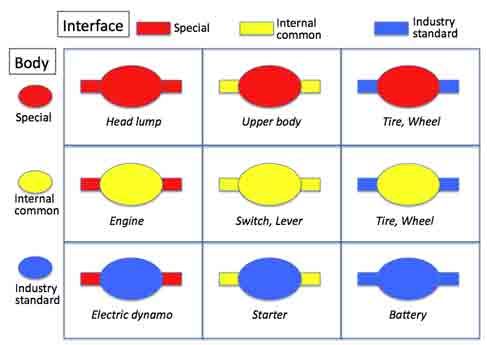

Car architecture: Degree of standardization of body and interface of car parts

Car architecture: Degree of standardization of body and interface of car parts- Openness of standardized parts, including body and interface:

- Car: less than 10%

- Home electronics: more than 30%

- PC: more than 50%

3. なぜ自動車では強かったのか:

- 自動車生産(世界と日本):

- 1980年以前の海外生産はほとんどなし

- 1990年代の市場シェアは、北米30%、EU10%、欧州非自動車生産国30%、東南アジア50-90%

- 日本の自動車産業は20C最後の四半紀に世界の主要生産国となった。

- IMVP報告書 (1979):

- 各自動車会社間の深層での競争力を学際的に比較。生産性のベンチマーキング、生産品質、リードタイムなど

- アーキテクチャ特性による自動車部品の分類:<左図>

- 設計のオープン度=本体およびインターフェイスの業界標準比率は

- 自動車:10%以下

- 家電:30%以上

- PC:50%以上

>Top 4.

Anatomy of manufacturing organization capability:

- Labor productivity = Production volume / Working hours

= (Production volume / Net working hours) x (Net working hours / Working hours)

= (Net working speed) x (Net working hour ratio)

- Toyota emphasized to improve (Net working hour ratio) by decreasing down time, tooling change time, and waste waiting time.

- Single function worker needs to respond speed up of production line

- Production lead time = (Net working hours) + (No receiving time of information)

- Deep layer production lead time:

- consists of efficiency, speed and accuracy of design information transfer

- Deep layer development lead time:

- consists of creation of design information, that is, efficiency, speed and accuracy of problem solving

- Powerful Project Manager:

- understands both languages and jargon of market and technical groups.

- proposes and promotes own concept: 'Product champion'

- such proposal should be easy-to-make design, prospectively adjusted among production engineering division, prototype factory, and big-volume factory (simultaneous engineering)

- Rapid communication:

- direct communication with market

- continuous and cumulative concept creation

- internal communication

- internal problem solving

- external communication

- overlap problem solving

- rapid problem solving

- Why such deep layer competitive dege lasts long?

4.

もの造り組織能力の解剖学:

- 労働生産性=生産性/労働時間

= (生産量/正味作業時間)× (正味作業時間/労働時間)

= (正味作業スピード)× (正味作業時間比率)

- トヨタは、正味作業時間比率の果然を重視。故障時間、段取り替え時間、手待ち時間の短縮など

- 単能工は、生産ラインのスピードアップに対応するよう求められる。

- 生産リードタイム=正味作業時間+情報を受領していない時間

- 深層の生産リードタイム:

- 設計情報の転写の効率、スピード、精度

- 深層の開発リードタイム:

- 設計情報の創造、問題解決の効率

- 重量級PM:

- 市場および技術グループの双方の言語、専門用語を理解

- 自身のコンセプトを提案・推進する:プロダクト・チャンピオン

- これらのデザインは作りやすい設計で、予め、生産技術、試作工場、量産工場間の調整を得ておく (サイマル・エンジニアリング)

- 迅速なコミュニケーション:

- 市場との直接情報連結

- 累積的なコンセプト創造

- 社内コミュニケーション

- 社内問題解決

- 社外コミュニケーション

- オーバーラップ問題解決

- 迅速な問題解決

- なぜこの深層競争力の優位は長続きするか

>Top 5. Japanese car industry in 20C:

- Japanese car industry in 20C:

- 1. At the dawn of car industry (1930s):

- Toyota and Nissan started truck production getting the license from Japanese government.

- Annual production is around 50K, while US 5M.

- Toyota reverse-engineered Ford and Chevrolet, and assembled the copied parts. Toyota's productivity was said about 10% of Form.

- NIssan bought blueprint and production facilities from Graham truck factory.

- Japanese three-wheeled cycle: simpler in structure and less parts. But its function terminated in 1960s.

- Toyota built its first full-scale assembly line at Koromo factory in 1938, whose monthly production was 2K (about 10% of US scale).

- 2. Streamlined production started (latter of 1940s):

- Domestic production: 30K in 1950, 70K in 1955.

- Toyota induced Ford production system and management style of Taylorism, and started partly just-in-time style.

- Domestic production increased: 500K in 1960, 5M in 1970, and then 11M in 1980.

- 11 Car manufacturers (9 passenger car manufacturers) by the middle of 1960.

- Car export: 40K in 1960, 1M in 1970, 6M in 1980 and peak was 6.7M in 1985 when Plaza accord was agreed strong yen.

around 4M in the latter half of 1990s due to higher yen and trade friction and off-shoring.

- Toyota attained 10 times productivity until 1955 (Taiichi Ohno, originator of Toyota production style)

- Mostly improved in software aspect in latter half of 1940s, such as standardization of operation, equalized production, layout change, multi-process handling. Concentrated production in the end of month was common because all necessary parts could not be collected until then.

- Factory layout: layout according to machine tools (drill machine, lathe machine, milling machine), thereafter according processing sequence

- 3. Creation of foundation (1950s):

- Toyota learned from Ford: 1) Suggestion system, proposal for improvement, and 2) TWI (Training Within Industry), learning of Taylorism management style.

- Toyota started TQC movement around 1960.

- Toyota started to induce Kamban (signboard) system, which post-process requires front-process to prepare necessary parts. Here Kamban (a signboard or a slip) intercommunicates cycling between these processes.

- Toyota built Motomachi integrated factory for passenger car (press, welding, coating, assembling), starting from 5K monthly, aiming 50K in five years. (almost equivalent capacity of US at last)

5.

20世紀の日本の自動車産業:

- 20世紀の日本の自動車産業

- 1. 自動車産業の黎明期 (1930年代)

:

- トヨタと日産は政府許可を得て、トラック生産開始。

- 年間約5万台 (米国は年間500万台)

- トヨタは、フォードやシボレーのリバースエンジニアリングによって生産。但し生産性はフォードの10%。

- 日産はグラハムのトラック工場から設計と生産設備を買収。

- 三輪車:構造が単純で部品数少ない。但しその役割は1960年代に終了。

- 1938年、トヨタ初の本格的組立工場である挙母工場を建設。月産2000台で、米国の規模の10%

- 2. 生産システムの合理化開始 (1940年代後半):

- 国内生産:3万台 (1950)、7万台 (1955)

- トヨタはフォードの生産システムやテイラー主義的な管理手法を導入し、部分的にはジャストインタイム開始。

- 国内生産;50万台 (1960)、 500万台 (1970)、1100万台 (1980)

- 1960年代半ばまでに、11社メーカー (内、乗用車は9社)

- 自動車輸出:4万台 (1960)、100万台 (1970)、600万台 (1980)、ピークは670万台 (1985、プラザ合意の年)、1990年代後半は、円高、貿易摩擦、海外生産もあり400万台前後。

- トヨタは1955年までに10倍の生産性を達成 (トヨタ生産方式の開祖・大野耐一)

- 1940年代後半は主にソフト面での改善が中心。作業の標準化、生産の平準化、レイアウト変更、多工程待ちなど

- 3. 基礎固めの時期 (1950年代)

- トヨタはフォードから学んだ。1) 創意工夫提案制度 (Suggention system)、および 2) テイラー主義的管理手法 (TWI)

- トヨタ、1960年頃よりTQC活動開始

- トヨタ、1950年代後半より、カンバン方式導入開始。後工程が前工程に必要が部品を取りに行く。看板は工程間の循環伝票。

- トヨタ、元町工場建設。乗用車一貫工場 (プレス、溶接、塗装、組立)、当初は月産5千台、5年後に5万台目指す (ようやく米国と同規模)

- 4. Motorization and mass production factory (1960s).:

- Order in unit: purchase sub-assembled parts from relatively small number of makers rather than purchase simple parts from many suppliers.

- Multiple and diversified suppliers: multiple car manufacturers purchase parts from same functional parts supplier (=primary parts supplier)

- Hierarchical parts suppliers:

Secondary parts suppliers are less than 100 employees, and third and fourth suppliers are micro business with less than 10 employees.

- From laying importance on acceptance inspection by car manufacturer to full participated quality control including parts suppliers.

- Cost reduction of parts: about 30% down during 1960 -65.

- 5. Export expansion and global competitiveness (1970s):

- Car export increased up to 5M during 1970s.

- Segmented US market: US full-sized car and Japanese compact car

- Request for good mileage since oil crisis: Honda's CVCC, Toyota's 3-way catalyst method

- Lean management: aiming profitable in the period of lower capacity utilization.

- 6. Globalization and further refinement of technology (1980s):

- Small-car battle: before Plaza Accord: Japanese compact car is $1500-2000 cheaper than US corresponding car.

- After Plaza Accord, car export maintained around 4M.

- Rapid incrementalism in Japan rather than reinvention or dematurity of automobile anticipated by an US journalism.

- International collaboration:

- Nissan, Toyota, Honda US factories

- Nissan UK factory

- Toyota-GM collaboration

- Nissan-Alfa Romeo J/V

- Honda-BL technical tie-up

- Mitsubishi-Crystler collaboration

- Isuzu-Suzuki-GM collaboration

- Matsuda-Ford collaboration

- Daihatsu-Innocenti collaboration

- Toyota-Lotus

- Slow down of productivity improvement:

- 6.3% in 1970s, but only 0.3% increase in 1980s.

- High cost structure:

- blunting of production site improvement

- continuous trend of excess design and excess quality

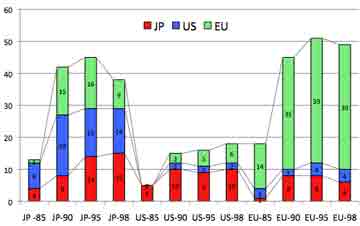

- IMVP (International Motor Vehicle Program) report by MIT

- 4. モータリゼーションと大量生産工場 (1960年代):

- ユニット発注:

- 納入先の多数化:複数の自動車メーカが同じ機能部品サプライヤー (一次部品メーカ) から購入する。

- 部品メーカの基本構造:二次部品メーカは100人以下、三次、四次部品メーカは10人以下の零細企業

- 従来の受入検査重視から、部品メーカを含む全員参加型の品質管理へ

- 部品の価格低減:1960-65年の間に約30%ダウン

- 5. 輸出拡大と国際競争力 (1970年代):

- 自動車輸出は、1970年代を通じ、500万台分増加

- 米国市場では、米国の大型車、日本の小型車の棲み分け市場

- 石油危機後の燃費改善要求:ホンダのCVCC、トヨタの三元触媒方式

- 減量経営:低層業度でも利益が出る体質

- 6. 国際化と技術の洗練化 (1980年代):

- プラザ合意以前:日本の小型車は米国のそれより$1500-2000安価

- プラザ合意以後は、輸出は400万台程度に推移

- 日本では、急速で小刻みなイノベーション (米国ジャーナリズムでは、自動車の再発明、脱成熟化を標榜)

- 国際協力:

- 日産、トヨタ、ホンダの米国工場

- 日産、英国工場

- トヨターGM提携など

- 労働生産性は鈍化

- 1970年代は6.3%、80年代は0.3%の上昇

- 高コスト構造:

- 現場改善の鈍化

- 過剰設計、過剰品質の常態化

- IMVP報告書

>Top 6.

Logic of emerging competency building:

- How organizational capability is built under competitive pressure?:

- Is this capability built based on ex ante rationality or ex post one?

- Organizational capability could be emergently or resultantly built.

- Multi paths in system emergence:

- Random trials

- Choices within environmental constraints

- Guided by corporate vision

- Target is set by rational calculation

- Japanese style production system:: a chance success:

- chronic labor shortage

- all-round worker avoiding excessive specialist

- unit delivery by parts makers (half assembled by approved drawing given)

- effective utilization of existing facility

- diversification of car models (annual production around 200K in 1980s)

- Technical transfer form Ford to Toyota:

- Ford: 10 times productivity than then Toyota

- Ford had Japanese plant (second half of 1920s - first half of 1930s) having 90% market share.

- learned assembly line, transfer machine (automated manufacturing machine), suggestion system

- Preparedness for improvement:

- Technical transfer from textile industry

- Job switch from aircraft industry

6.

創発的な能力構築の論理:

- 組織的な能力は競争的圧力の下でどのように構築されるか

- この能力が事前合理的か、それとも事後合理的に構築されるか?

- 組織能力は創発的、すなわち結果として構築される。

- 多経路的なシステム創発: (左図)

- 偶然試行

- 環境制約

- 企業のビジョン

- 合理的な計算に基づく目標設定

- 日本的生産システム:怪我の功名

- 慢性的な労働不足

- 多能工 (過剰専門家を防ぐ)

- 部品メーカによるユニット納入 (承認図により半分組み上がった機能部品調達)

- 既存設備の有効活用

- フォードから学習:

当時のトヨタより10倍の生産性

- 1920年代後半〜30年代前半:日本工場のシェア90%

- 流れ作業組立、トランスファーマシン (自動加工ライン)、提案制度

- 改善への心構え

- 繊維産業からの技術移転

- 航空機産業からの転職

>Top 7. Trade friction as a supporting cast:

- Why competition, dispute, and collaboration concurrently occured and expanded in world car industry during 1980s and 90s?

- Then it had been frequently reported escalation of global competition, intense trade friction, and report of collaboration betwwen car manufacturers.

- Is collaboration among firms

a kind of cartel?

- price competition is assessed by customers, while capability building competiton by neutral evaluators (academia or specialists)

- Trade friction (actually between US and Japan):

- Trade friction has shown nothing but a secondary character, which has given a kind of moratorium of time to US manufacturers.

- Capability building competion has been a principal character.

- Weaker competitive manufacturers have not resurrected.

- Remark:

What would happen nationalized GM and Chrystler? .... 2009/6)

- Barren controversy:

- US asserts unfair opening of Japanese market

- Japan asserts lack of effort for competitiveness

- 1970s-80s:

- mostly settle by restoriction of export of Japanese products to US

- increase of local production capacity of Japanese car.

- 1980s-90s:

- expansion of import of US products to Japan

- US cars import: increased up to 160,000 in 1995, but leveled down to 50,000 in 2000

- Capacity building competitin has been a main character, but trade friciton has played no more than side character.

7.

脇役としての貿易摩擦:

- 1980-90年代の世界の自動車産業において、なぜ競争、紛争、協調が同時に起きて拡大したのか

- 当時は頻繁に、国際競争の激化、貿易摩擦の激化、自動車会社間の連携報道

- 企業間の協調はカルテルなのか?

- 顧客に評価された価格競争、一方、能力構築競争は中立的な評価者 (学界、専門家)による

- 貿易摩擦 (実質的には日米間の):

- 貿易摩擦は脇役に過ぎなかった。それは米国メーカに時間的猶予を与えた。

- 能力構築競争こそが主役であった。

- 弱い競争力のメーカは復活しなかった。

- 注): 国有化されたGM, Chryslerはどうなるのか?... 2009/6)

- 水掛け論:

- 米国:日本市場開放の不公平さを指摘

- 日本:米国企業の競争努力不足を指摘

- 1970-80年代:

- 多くの場合、日本製品の対米輸出制限で決着

- 日本自動車の現地生産増加

- 1980-90年代:

- 米国製品の日本への輸入増加

- 米国車の輸入:1995年に16万台、2000年には5万台に落ち込み

- 主役はあくまで能力構築競争で、貿易摩擦は脇役を演じてきたに過ぎない。

>Top 8. Cooperative network complementing competition:

Collaboration among car manufacturers:

Collaboration among car manufacturers:- Pattern of collaboration:

- Strong coupling:

M&A or majority equity participation

- Weak coupling:

minor equity participation, J/V, technical cooperation, OEM supply of parts or finished car, joint development, sales cooperation, etc.

- Type of collaboration:

- Capital alliance: equity participation or M&A

- Joint venture:

- Technical cooperation: supply of finished car, parts supply, or joint production

- Sales cooperation:

- 1980s -90s:

- Most cases were weak coupling.

- Manufacturing by volume efficiency:

- In the latter 1990s it is widely reported that

- Number of world survivor of car manufacturers: 10

- Appropriate volume efficiency: around 4M per annum

- But this report has no reasons:

- Flexible production system had been established since 1980

- Development cost per car showed to decrease.

- But why an optimum production increased from 2M to 4M per annum?

8. 競争を補完する提携ネットワーク:

- 自動車会社間連携:<左図>

- 提携パターン:

- 強い連結:

M&A、マジョリティ投資

- 弱い連結:

マイナー投資、JV、技術協力、部品や完成者のOEM供給、共同開発など

- 1980-90年代:

- 弱い連結が多数

- 量産効果:

- 1990年代後半

- 世界の生き残り10社

- 量産レベル:年産400万台

- この報道根拠なし

- 1980年以降フレキシブル生産システム確立

- 1台当たり開発コストは減少

- なぜ最適生産量が200万台から400万台に増加したのか?

>Top 9. Catch-up from US and Europe:

- Lean production and fat product:

As the background:

- Too many types

- Lower common parts

- Too many model changes: 4 years cycle in Japan

- Overengineering and overquality

- Price of used cars indicates adequacy of engineering:

- Afterthought:

Generation mechanism of overengineering or over adaptation (overkill)

- Too short period to make rational and simplified designing.

- Too responsive to customer satisfaction: please-everyone designing (neither unsatisfactory nor satisfactory)

- High-end product designing

- Abuse of high production capacity

- Too much designing by super PM

9.

欧米からの追い上げ:

- リーンな生産とファットな製品:

(リーン=無駄が少ない;ファット=無駄が多い)

背景としては、

- 車種が多い

- 部品の標準化

- 頻繁なモデルチェンジ:4年サイクル

- 過剰設計、過剰品質

- 中古車価格は、設計の適切性を示唆

- 反省点:過剰設計、あるいは過剰適応の発生メカニズム

- 合理的かつ簡素な設計をするには短期間過ぎた

- CS手法の使いすぎ

- 高級化路線の行きすぎ

- 高い製造能力の乱用

- 重量級PMによる過剰設計

>Top 10. capability building competition still continues:

- Still continuing global competition of capacity building.

- Impact of development of IT technology (Front loading)

- Simulation model by CAE

- Rapid prototype by using 3D CAD

- IT/LT Paradox: IT investment does not correlate with shortening of lead time (LT)

- IT utilization is a necessary condition, but not sufficient one.

- Capacity building competition in 21C: Three scenarios

- Disappearance of the product from the market

- Obsolescence of architecture and accumulated elemental technology, though the product itself remains.

- Obsolescence of established organizational power due to drastic change of production technology and system, though the product is primarily unchanged.

- Original Sin of car industry:

- Aerial pollution

- Emission of carbon dioxide

- Consumption of fuel energy

- Traffic accident

- Architecture of 21C car:

- Hybrid car

- Clean diesel engine

- Natural gas

- Biomass

- Battery car: nickel-hydride cell and lithium-ion cell

- Fuel cell (by chemical reaction between hydrogen and oxygen)

10.

能力構築は続く:

- 能力構築のグローバルな競争は現在も進行中

- IT技術進歩のインパクト

- フロントローディング

- CAEによるシミュレーションモデル

- 3D CAD利用によるラピッド・プロトタイプ

- IT/LTパラドックス:IT投資が必ずしもリードタイムの短縮につながらない。

- IT活用は必要条件であるが、十分条件ではない。

- 21世紀における能力構築競争:3つのシナリオ

- 当該製品が市場から消去

- 製品自体は残るが、アーキテクチャや獲得した要素技術が陳腐化

- 製品は根本的に不変だが、生産技術やシステムが劇的に変化して、構築してきた組織能力が陳腐化

- 自動車産業の原罪:

- 大気汚染

- 二酸化炭素発生

- 化石エネルギー消費

- 交通事故

- 21世紀の車のアーキテクチャ:

- ハイブリッド

- クリーン・ディーゼル

- 天然ガス

- バイオマス

- 電気自動車:ニッケル水素、リチウムイオン

- 燃料電池 (水素と酸素の化学反応)

Comment

- Comparision of IT industry and car industry is very interesting; the former shows network externarity, but the latter does not. The former industry is typically commoditized goods, the latter is integrated goods partially using commoditized parts.

- Digital goods are easy to compare good or bad, fast or slow, or expensive or cheap, but analogical goods show various flavor, tint, or taste related to each cultural background.

- It is car that should have the value of beauty, sensitivity, pleasure and creation.

- The above strengh of Japanese production would become incompetitive by the total replacement of EV, which is essentially digitized commodity product. (2017)

- IT産業と自動車産業との比較は興味深い。前者はネットワークの外部性を示し、後者はそうでない。前者は典型的なコモディティ商品であり、後者は部分的にはコモディティ部品を使用しながらも擦り合わせの商品である。

- デジタル商品は善悪、遅速、高低の比較が容易であるが、アナログ商品は各々の文化を背景としたさまざまな香り、色合い、味を示す。

- 自動車こそ持つべきは、美感遊創の価値であろう。

- ガソリン車がEVに全面的に置き換えられると、上記の強みは一気に牛なる可能性がある。(2017)

Title |

Capability Building Competition |

能力構築競争 |

|---|---|---|

Index |

|

|

Why? |

|

|

Resume |

要約 |

>Top 0. Industry observed from field site:

|

0. もの造りの現場からの産業論:

|

>Top 1. Essence of competition in car industry:

|

1. 自動車産業における競争の本質:

|

>Top 2. What is capability building competition?:

|

2. 能力構築競争とは:

|

|

|

>Top 3. Why Japanese car industry has been strong?:

|

3. なぜ自動車では強かったのか:

|

>Top 4. Anatomy of manufacturing organization capability:

|

4. もの造り組織能力の解剖学:

|

>Top 5. Japanese car industry in 20C:

|

5. 20世紀の日本の自動車産業:

|

|

|

>Top 6. Logic of emerging competency building:

|

6. 創発的な能力構築の論理:

|

>Top 7. Trade friction as a supporting cast:

|

7. 脇役としての貿易摩擦:

|

>Top 8. Cooperative network complementing competition:

|

8. 競争を補完する提携ネットワーク:

|

>Top 9. Catch-up from US and Europe:

|

9. 欧米からの追い上げ:

|

>Top 10. capability building competition still continues:

|

10. 能力構築は続く:

|

Comment |

|

|